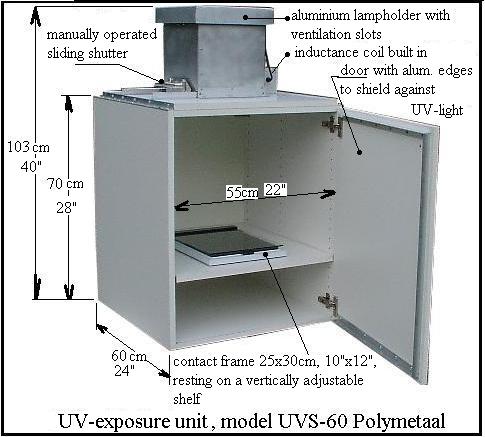

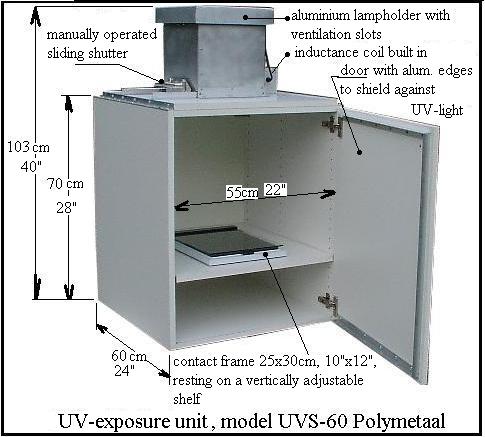

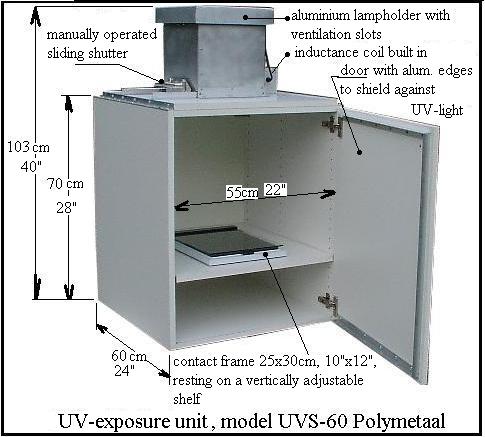

User's instructions exposure unit UVS-60,

Polymetaal

General information about photopolymer.

An Ultra Violet exposure unit is used to expose a light sensitive

emulsion to Ultra Violet light. This particular emulsion is a

photopolymer. A photopolymer is a plastic of which some properties

change if exposed to light. An unexposed emulsion consists of

"monomer" molecules without much cohesion. As soon as these monomers

are exposed to light, they change into polymers which means that the

molucules form links and chains with other molecules. A "monomer"

molecule can be washed out easily with with a water/soda solution,

while a "polymer" molecule appears to us as "hardened out" because of

the links and chains it forms with other molecules, hence it cannot

be washed out to easily with a water/soda solution.

The light sensitive emulsion can be applied to a plate in various

ways;

- A liquid emulsion can be applied to a plate with an aerosol

spray or with a brush. Another way is the use of a turntable; a

drop of liquid is dropped on to the middle of the plate on the

turntable. The centrifugal forces will distribute the liquid

evenly over the plate. In this manner a very thin and even layer

kan be accomplished.

- The light sensitive emulsion is also available as a film, on a

roll. The sensitive layer is very fragile and is therefore

protected on both sides with a transparant mylar layer. This film

can be applied to the plate in different ways. (see instructions

for ImagOn, ImagOn Ultra, Riston and Puretch).

- Also available are plates with a ready made layer of

photopolymer on top (Toray, Solar plates). These plates are used

in commercial (relief)printing as an alternative for the old lead

clichés. Because of the thickness of the layer (appr.

0,5mm) these plates mainly used for relief printing. (Dianne

Longley's "Printmaking with Photopolymer Plates" or Dan Welden's

book "Printmaking in the Sun").

The sort of material to be used for the support of the polymer

plate depends upon the final purpose. It is obvious that the support

must be able to resist the pressure of an etching press. This already

limits the choise to metal and some plastics. The "Toray plates" or

"Solar plates" for example have a support made of a steel sheet of a

few tenth's of a mm thickness.

- If a film can be laminated onto a plate, it is very important

to realize this this allows the plate to be handled and printed

like any other intaglio plate. Photopolymer films come in

several thicknesses; For example the ImagOn (Ultra) films are

about 50 microns (0,05mm) thick. This thickness makes these films

very suitable for the "Non-etch-techniques".

In a "non-etch-technique" the film is exposed in the contact frame

through a transparant sheet of plastic that carries the image. In

the next step the polymer is washed out in a water/soda solution.

The unexposed areas in will be washed out and show up as grooves

in the film. The exposed areas will not be washed out and remain

intact. After drying the plate in a drying cabinet the plate can

be inked and printed. After inking and wiping the "grooves" only

contain ink, the same way as in "traditional" intaglio. The

difference here is that the grooves are only present in the layer

of photopolymer and not in the metal plate beneath it. The metal

plate is therefore used only as support in order to keep the film

and hence the image together.

- If the emulsion is applied on to the plate as a liquid, this

results normally in a very thin layer. (5-20 micron). Some

photopolymer films are also quite thin (Puretch or Blue Shot). If

one uses these thin layers of film for a "non-etch-technique"

there will be a problem when printing a dark black. The film is

not thick enough to contain, when etched, enough ink in order to

print a dark black. These thin layers are not to be used for

non-etching-techniques. They are however very suitable for

"etching-techniques". In these techniques the polymer is used as a

resist. The preparation and exposure are more or less the same as

with a "non-etch-technique" but the development times in the soda

bath are longer. The unexposed area's are completely washed off

from the plate. The exposed areas are hard and will remain intact.

Next the plate is etched (in iron-per-chloride, ferric-chloride).

The grooves and dots will not be created in the film, but in the

copper or zinc plate. After etching the plate is cleaned in a more

concentrated bath of water and soda. In this bath also the

hardened polymer will also dissolve after about 10 minutes. The

plate can now be inked and printed in the normal way. This

technique also allows you to add to the plate other techniques

like dry point or engraving. In the "etch-techniques" the support

of the film becomes the forme to print from.

Use of the UV exposure unit

- Use the exposure unit only in areas where direct daylight has

no access. Daylight contains UV-light and can influence the

photopolymer. Low intensity normal tube light is no problem.

- Insert the plug into the mains. The UV-light will start, but

first with a low intensity. After a few minutes full intensity is

reached. Therefore, the lamp should be kept on during a session.

The sliding shutter must be used to start and stop the

exposure.

- Open the glass cover of the contact frame (or vacuum-frame).

Place the plate in the contact frame with the sensitive layer

pointing upwards.

- The transparant plastic sheet carrying the image is put on top

of the plate with the image side pointing downwards. Close now the

contact frame. It is very important that there is no space between

the image on the sheet and the light sensitive layer. If there is

space, it will probably lead to a fuzzy print.

- Record the time. Decide when the shutter must be opened and

closed. The exposure time depends upon many things but will

probably be around 2 or 3 minutes. Carry out the exposure.

- After exposure the contact frame is openened and the plate is

taken out. The image can be seen vaguely on the film

(ghost-image). The plate is now ready to be developed in the soda

solution.

Points of attention:

- At this time only the contact frame of 25x30cm (10"x12") is

available and comes with the exposure unit. For some printmakers

this size is good enough, especially while learning to work with

these techniques. For others however, bigger sizes are needed.

Polymetaal will develop in the future a contact frame of 50x60cm.

It is possible that it will have to become a vacuumframe. Check

this page regularly to find out recent developments.

- The distance between the contact frame and the lamp is

adjustable; therefore the smaller the print the shorter the

distance as well as a shorter the exposure time. If one needs the

full size of 50x60cm, the contact frame must be in the lowest

position.

Use the "back-button" to return to

the previous page.